A Full-Process Insight: From Granules to Finished Parts

In modern industrial production, accessories and components may be small in size, but they are critical for ensuring equipment performance and safety. Many essential industrial parts—such as electrical connectors, tool handles, pipe fittings, and protective covers—are made from a versatile yet powerful material: PVC injection compounds? Let’s uncover how PVC injection processing empowers industrial components, tracing the journey from raw material to finished product.

1. Starting Point: The Customizable Advantage of PVC Compounds

PVC (Polyvinyl Chloride) compounds, as a thermoplastic material, have become a “star player” in industrial injection molding due to their exceptional versatility.

Adjustable Hardness: Available from flexible to semi-rigid grades, meeting different mechanical requirements.

Strong Chemical Resistance: Resistant to oils, acids, alkalis, and various industrial media.

High Stability: With additives such as heat stabilizers, UV stabilizers, and flame retardants, service life is extended.

Eco-Friendly Options: Non-phthalate, RoHS-compliant, and recyclable grades available to meet sustainability demands.

These advantages make PVC not just a material, but a highly customizable solution.

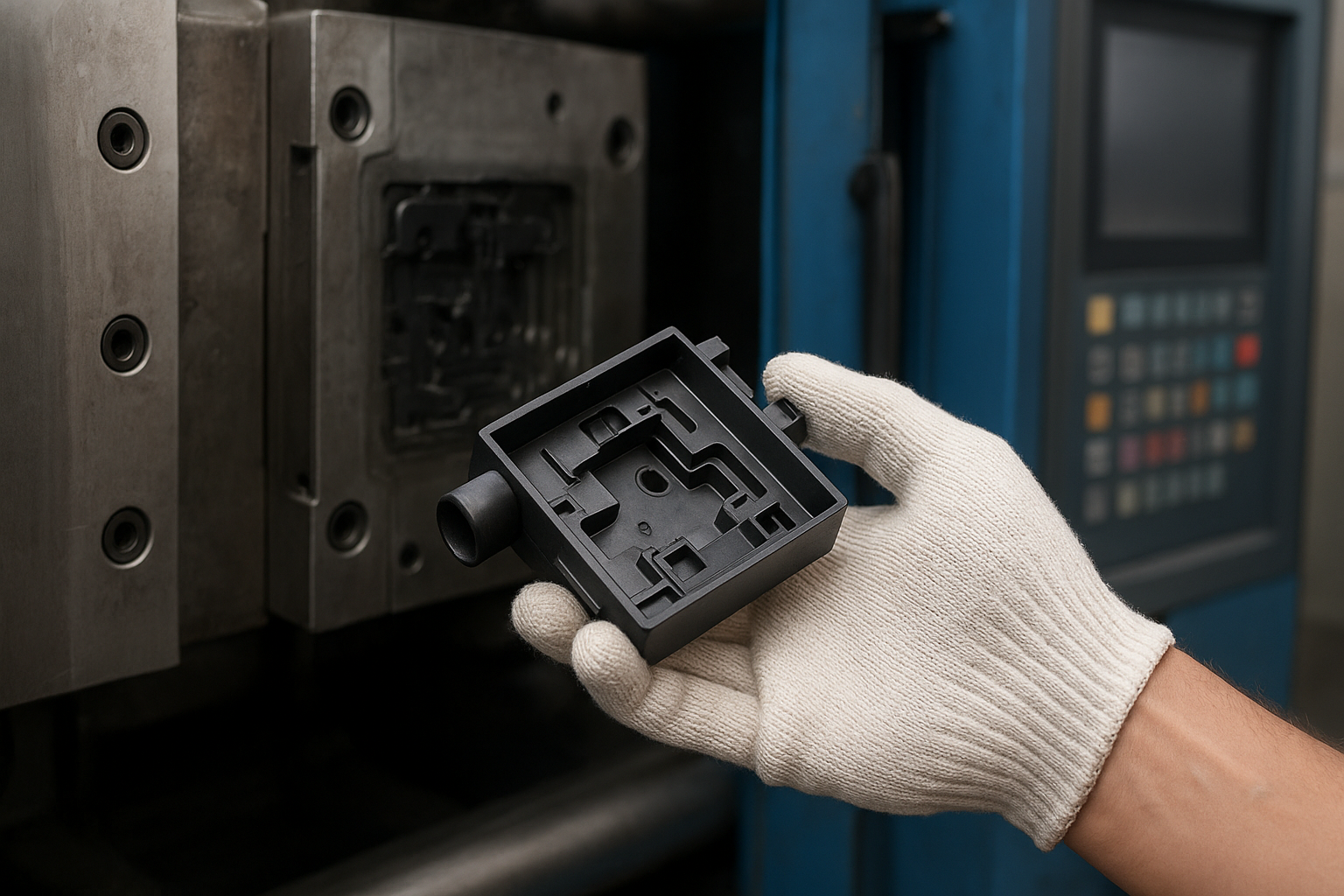

2. The Shaping Process: Precision and Efficiency in Injection Molding

How do PVC compounds transform into precise industrial parts? The key lies in the injection molding process.

Feeding & Plasticizing: Granules are fed into the injection machine, heated, and melted into a flowable state.

Injection & Filling: Under high pressure, the molten PVC is injected into the mold, filling even complex structures.

Cooling & Solidifying: The part cools inside the mold, achieving precise dimensions and stability.

Demolding & Finishing: Finished parts are ejected, trimmed, and tested before application.

Thanks to this efficient process, PVC compounds can be molded into products ranging from just a few grams to several kilograms, from simple sleeves to complex components.

3. Applications: The “Invisible Power” of PVC Components

PVC injection components are widely used across industries:

Electrical: Cable connectors, housings, and insulation parts for electrical safety.

Machinery: Protective covers, seals, and cushions for durability and ergonomics.

Piping Systems: Fittings, valve handles, and seals to ensure stable fluid transport.

Tools & Hardware: Screwdriver handles, plier grips, and sleeves for better grip and wear resistance.

Though often overlooked, these small PVC parts play critical roles in protection, connection, and support.

4. Empowering the Industry: Future Directions of PVC

With ongoing industrial upgrades and growing environmental demands, PVC injection materials are moving toward greener, smarter, and more functional solutions:

Eco-Friendly Formulations: Non-toxic, low-VOC, and recyclable options gaining popularity.

Functional Enhancements: Antibacterial, self-lubricating, and flame-retardant additives for extended use cases.

Smart Manufacturing: Integration with automated injection molding and intelligent quality control ensures efficiency and consistency.

From raw material design to precise molding technology, and from diverse applications to future innovations, PVC injection compounds empower industrial component manufacturing with flexibility and reliability. Like “silent heroes,” these small PVC parts are working behind the scenes to safeguard efficiency, safety, and sustainability in modern industry.

Post time: Sep-09-2025