Here’s a professional explanation of the production aspects of rigid injection-grade PVC pellets:

Rigid injection-grade PVC pellets are commonly used as raw materials for manufacturing rigid injection-molded products. PVC, short for polyvinyl chloride, is a widely used thermoplastic polymer known for its excellent mechanical properties, chemical resistance, and electrical insulation. The production process for rigid injection-grade PVC pellets involves several key steps and considerations.

1.Raw Material Preparation:

The production of rigid injection-grade PVC pellets requires the preparation of specific raw materials. These typically include PVC resin, additives, and fillers. The resin serves as the main component of PVC, while additives such as stabilizers, plasticizers, and lubricants are incorporated to enhance processability and physical properties. Fillers may be added as well to adjust and enhance the characteristics of the PVC pellets.

2.Batch Processing:

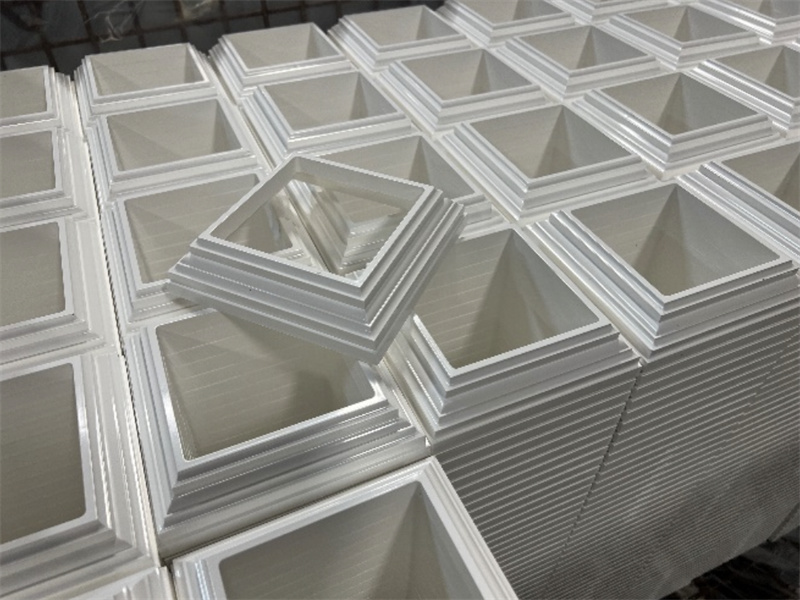

The production of rigid injection-grade PVC pellets usually involves batch processing. The raw materials, after being screened and dried, are introduced into a mixer. Inside the mixer, the materials undergo fusion and thorough mixing to ensure uniform dispersion. The resulting mixture is then fed into an extruder or injection molding machine for plasticizing and shaping. During plasticization, the material is heated to a specific temperature to melt and form the desired pellet shapes through the processing components of the extruder or injection molding machine.

3.Precision Processing and Screening:

Once the pellets are formed, they undergo precision processing and screening to remove impurities and ensure quality and consistency. These steps help to ensure the purity and uniformity of the PVC pellets.

4.Packaging and Storage:

After producing compliant rigid injection-grade PVC pellets, they are packaged, typically in bags or big bags. The packaged pellets are then stored in dry and well-ventilated conditions to prevent moisture absorption and maintain product quality.

It’s important to note that the production process for rigid injection-grade PVC pellets may vary depending on the manufacturer and equipment. This explanation provides a general overview, and additional factors such as temperature, time, and specific machinery may also be considered in practice. Furthermore, adherence to safety protocols and environmental regulations is crucial throughout the production process to ensure safety and sustainability.

Please keep in mind that this is a brief explanation, and the actual production process of rigid injection-grade PVC pellets may involve more specialized knowledge and complex steps. For detailed production processes and technical specifications, consulting professional PVC pellet manufacturers or experts in the field is recommended.

Post time: Jul-18-2023