ODM OEM Pvc Polyvinyl Chloride Raw Material For Extrusion Factories Exporter – PVC Compounds for Sheathing and Insulation Wire & Cable – INPVC

ODM OEM Pvc Polyvinyl Chloride Raw Material For Extrusion Factories Exporter – PVC Compounds for Sheathing and Insulation Wire & Cable – INPVC Detail:

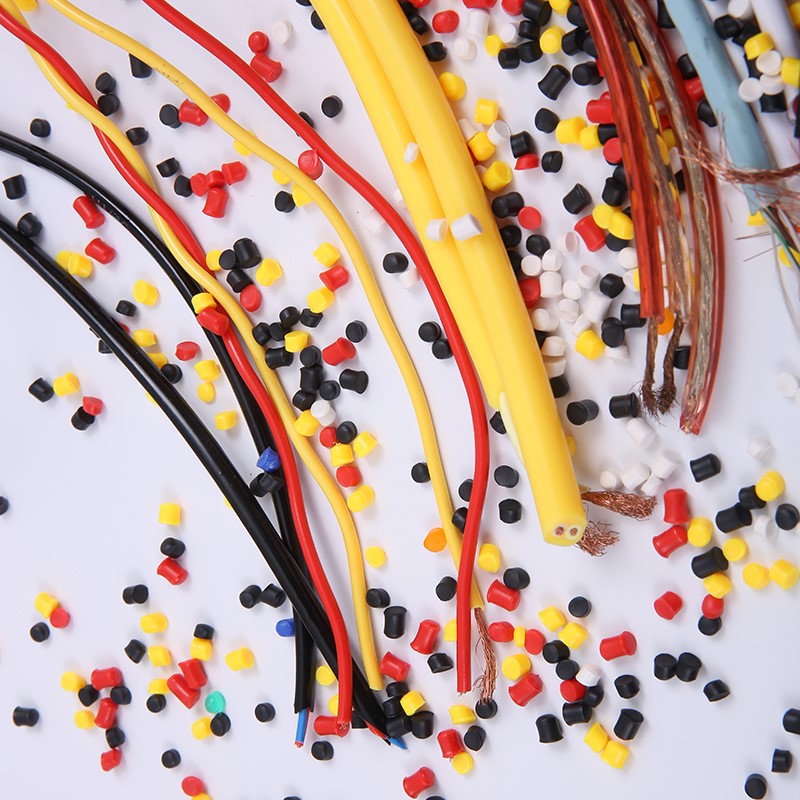

We are a leading manufacturer and suppliers of PVC Cable Compound for sheathing & Insulation with all international standards.

INPVC offers PVC cable compounds with RoHS and REACH. We can also customize all properties and colors as customer’s requirements. We also provide high-heat, low-smoke and flame-retardant properties, making them ideal for wire and cable applications. The benefits of using PVC compounds for cables include cost effectiveness, flame retardancy and durability.

Wire and Cable Insulation Compounds

Wire and Cable Sheathing Jacket Compounds

TI1 General Purpose Insulation PVC Compound (70°C)

TM1 General Purpose Sheathing PVC Compound (70°C)

TI2 Flexible Cable Insulation PVC Compound (70°C)

TM2 Flexible Cable Sheathing PVC Compound (70°C)

TI3 Heat Resistant PVC Insulation Compound (90°C)

TM3 Heat Resistant PVC Sheathing Compound (90°C)

ST- 1 General Purpose PVC Sheathing Compound

ST- 2 General Purpose PVC Sheathing Compound

FR (Flame Retardant) Insulation Compound

FRLS (Flame Retardant Low Smok) Compound

HR (Heat Resistant) PVC Cable Granules

RoHS & REACH Compliant Compounds

UL Compliant Compounds

Lead Free Compounds

Low Temperature (-40℃) Resistant Compound

● 70 °C & 90 °C PVC Insulation Sheathing

● 105 °C Automotive Cables

● IEC 60502-1 Cables

● House holds wires & cables

● Automotive Wire and Cable

● Fire Survival Cables

● Electric appliances wires

● Building PVC Wire and Cable

● Special Cable (Instrumentation Cables, Co-axial Cables, Control Cables, Fire Alarm Cables)

● Power Cables (Low Voltage Cables, Medium Voltage Cables)

● Signal,Communication & Data Cables

● Telecommunication cables (telephone cables, data transmission cables)

● Domestic and industrial cables

● Elevator Cables

● 300/500V Domestic Cables(FR)

● 600/1000V Industrial Cables(FR)

1. Colors: NAT: Natural, WHT: White, BLK: Black, RED: Red, GRY: Gray

|

Property |

Test Method |

Unit |

Specification |

||||||||

| Application |

|

|

Insulation |

Insulation |

Insulation |

Sheathing |

Sheathing |

Insulation |

Insulation |

Sheathing |

Sheathing |

| Standard |

|

|

TI1 |

TI2 |

TI3 |

TM1 |

TM2 |

Type 2 |

Type 5 |

Type 6 |

Type 9 |

| Density |

ISO 1183 |

g/cm3 |

1.45 ÷ 1.55 |

1.45 ÷ 1.55 |

1.45 ÷ 1.55 |

1.45 ÷ 1.55 |

1.45 ÷ 1.55 |

1.45 ÷ 1.55 |

1.45 ÷ 1.55 |

1.45 ÷ 1.55 |

1.45 ÷ 1.55 |

| Hardness |

ASTM D 2240 |

Shore A |

87 ÷ 90 |

80 ÷ 85 |

88 ÷ 90 |

87 ÷ 90 |

80 ÷ 85 |

90 ÷ 92 |

90 ÷ 92 |

80 ÷ 85 |

88 ÷ 90 |

| Tensile strength |

IEC 60811-1-1 |

N/mm2 |

≥ 12.5 |

≥ 10.0 |

≥ 15.0 |

≥ 12.5 |

≥ 10.0 |

≥ 18.5 |

≥ 12.5 |

≥ 6.0 |

≥ 12.5 |

| Elongation |

IEC 60811-1-1 |

% |

≥ 125 |

≥ 150 |

≥ 150 |

≥ 125 |

≥ 150 |

≥ 125 |

≥ 125 |

≥ 125 |

≥ 150 |

| Aging condition |

IEC 60811-1-2 |

|

80°C x 7D |

80°C x 7D |

135° x 14D |

80°C x 7D |

80°C x 7D |

- |

135°C x 10D |

- |

100°C x 7D |

| Tensile strength after aging |

|

N/mm2 |

≥ 12.5 |

≥ 10.0 |

≥ 15.0 |

≥ 12.5 |

≥ 10.0 |

- |

≥ 12.5 |

- |

≥ 12.5 |

| Variation |

|

% |

≤ ±20 |

≤ ±20 |

≤ ±25 |

≤ ±20 |

≤ ±20 |

- |

≤ ±25 |

- |

≤ ±25 |

| Elongation after aging |

|

% |

≥ 125 |

≥ 150 |

≥ 150 |

≥ 125 |

≥ 150 |

- |

≥ 125 |

- |

≥ 150 |

| Variation |

|

% |

≤ ±20 |

≤ ±20 |

≤ ±25 |

≤ ±20 |

≤ ±20 |

- |

≤ ±25 |

- |

≤ ±25 |

| Heat shock test 150°C x1hr |

IEC 60811-3-1 |

- |

No crack |

No crack |

No crack |

No crack |

No crack |

No crack |

No crack |

No crack |

No crack |

| Loss of massAging condition |

IEC 60811-3-2 |

mg/cm2 |

≤ 2.0 80°C x 7D |

≤ 2.0 80°C x 7D |

≤ 1.5 115°C x 10D |

≤ 2.0 80°C x 7D |

≤ 2.0 80°C x 7D |

≤ 2.0 80°C x 7D |

≤ 1.5 115°C x 10D |

≤ 2.0 80°C x 7D |

≤ 1.5 100°C x 7D |

| Volume resistivity at 27°C |

ASTM D257 |

Ω.cm |

≥ 1013 |

≥ 1013 |

≥ 1014 |

- |

- |

≥ 1014 |

≥ 1014 |

- |

- |

| Thermal stability at 200°C |

IEC 60811-3-2 |

min |

≥ 60 |

≥ 60 |

≥ 240 |

≥ 60 |

≥ 60 |

≥ 60 |

≥ 60 |

≥ 60 |

≥ 60 |

| Low temperature test |

IEC 60811-1-4 |

°C |

-15 |

-15 |

-15 |

-15 |

-15 |

-15 |

-15 |

-15 |

-15 |

2. FR: Flame Retardant, TR: Termite Resistant, UV: Ultra‐Violet Stabilized, OR: Oil Resistant

|

Basic Features |

. Eco-friendly . No Smell. Non Toxic |

|

· Excellent Durability |

|

|

. Bending Resistant . Abrasion Resistant |

|

|

. Excellent Moulding Properties |

|

|

. RoHS & REACH Grade |

|

|

. Customized Properties |

|

|

. Outstanding Chemical and Physical Properties |

|

|

. Bright and Uniform Color |

|

|

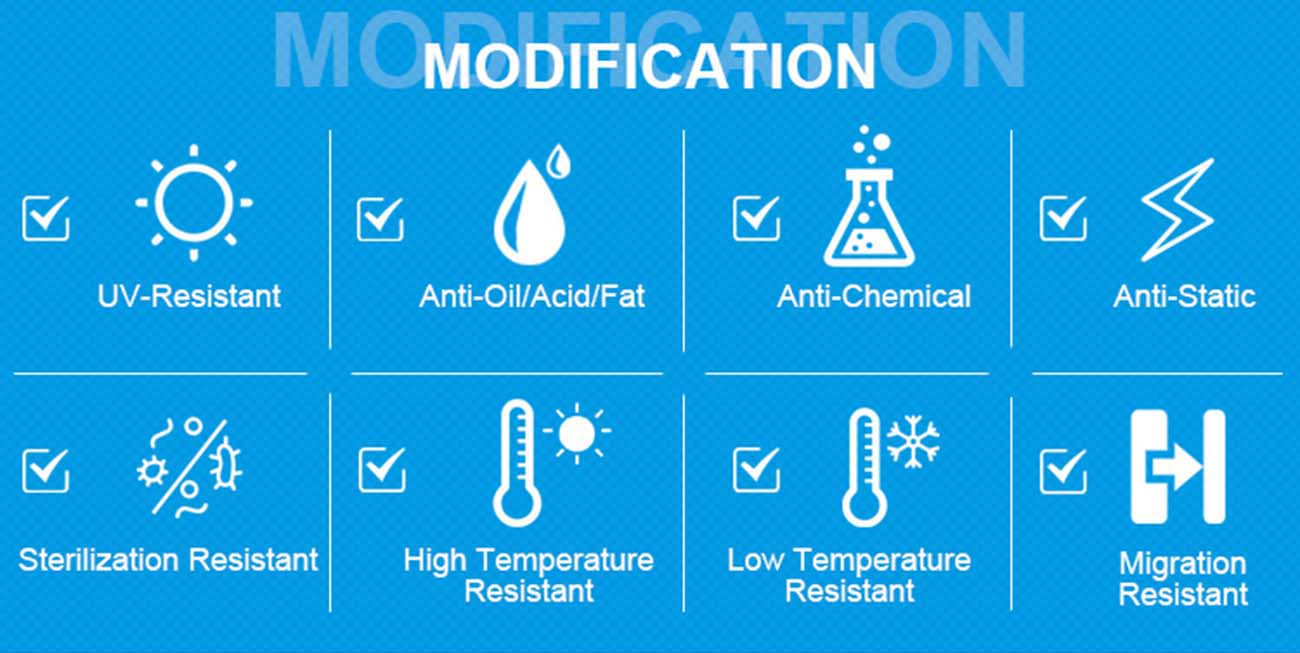

Modified Character |

UV-Resistant |

|

Anti-Oil /Acid /Gasoline / Ethyl Alcohol |

|

|

Migration Resistant |

|

|

Anti termite.Anti rodent |

|

|

Sterilization Resistant |

|

|

Low Temperature Resisitance |

|

|

Heat Resisitance |

|

|

Low-Smoke |

|

|

Flame-Retardant |

|

|

Our Advantage |

Excellent quality,Reliable & consistent quality |

|

Competitive prices,Reliable & just in-time delivery |

|

|

Short delivery period |

|

|

Advanced technology |

|

|

Innovation and continuous improvement |

|

|

With vast experience of 30 years |

|

|

Technical support for applications / projects |

|

|

Product development for a changing market |

|

|

Product modification can be carried out according to customer requirements |

Product detail pictures:

Related Product Guide:

Assume full responsibility to satisfy all needs of our clients; achieve continual advancements by endorsing the expansion of our purchasers; turn into the final permanent cooperative partner of clientele and maximize the interests of clients for ODM OEM Pvc Polyvinyl Chloride Raw Material For Extrusion Factories Exporter – PVC Compounds for Sheathing and Insulation Wire & Cable – INPVC , The product will supply to all over the world, such as: Belgium, Belgium, Madras, We have more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the "client first" principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information please do no hesitate to contact us..

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!