PVC Compounds for Sheathing and Insulation Wire & Cable

We are a leading manufacturer and suppliers of PVC Cable Compound for sheathing & Insulation with all international standards.

INPVC offers PVC cable compounds with RoHS and REACH. We can also customize all properties and colors as customer’s requirements. We also provide high-heat, low-smoke and flame-retardant properties, making them ideal for wire and cable applications. The benefits of using PVC compounds for cables include cost effectiveness, flame retardancy and durability.

2. FR: Flame Retardant, TR: Termite Resistant, UV: Ultra‐Violet Stabilized, OR: Oil Resistant

|

Basic Features |

. Eco-friendly . No Smell. Non Toxic |

|

· Excellent Durability |

|

|

. Bending Resistant . Abrasion Resistant |

|

|

. Excellent Moulding Properties |

|

|

. RoHS & REACH Grade |

|

|

. Customized Properties |

|

|

. Outstanding Chemical and Physical Properties |

|

|

. Bright and Uniform Color |

|

|

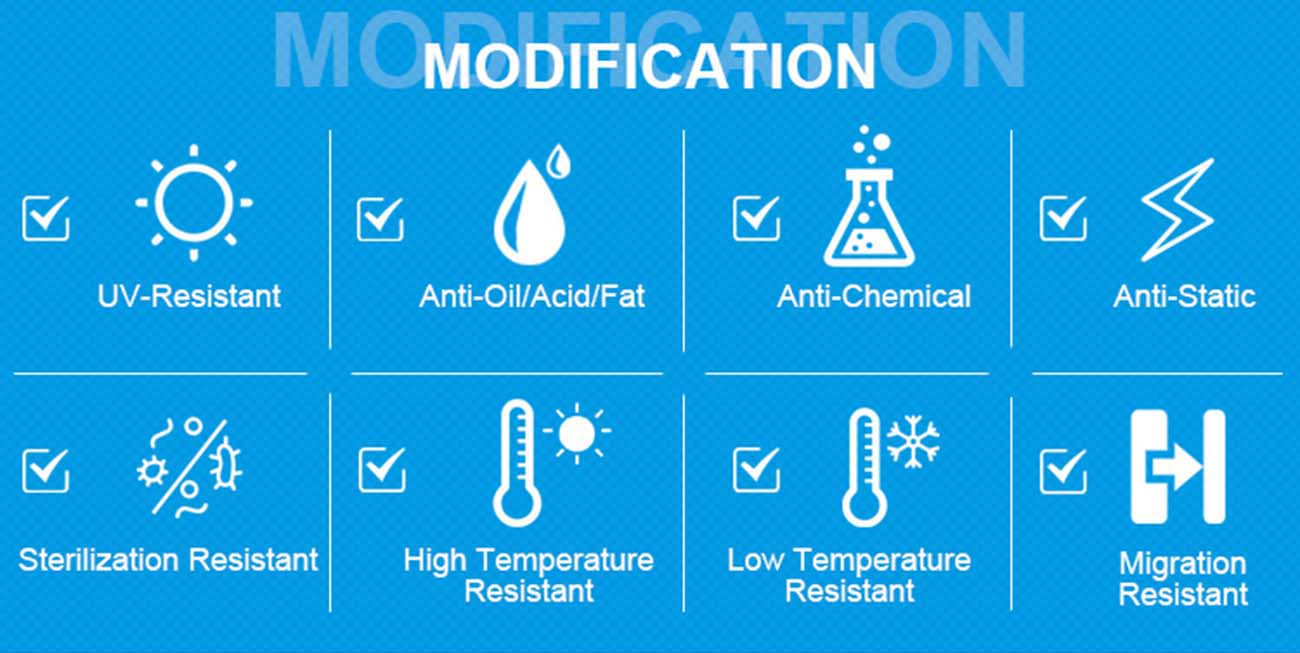

Modified Character |

UV-Resistant |

|

Anti-Oil /Acid /Gasoline / Ethyl Alcohol |

|

|

Migration Resistant |

|

|

Anti termite.Anti rodent |

|

|

Sterilization Resistant |

|

|

Low Temperature Resisitance |

|

|

Heat Resisitance |

|

|

Low-Smoke |

|

|

Flame-Retardant |

|

|

Our Advantage |

Excellent quality,Reliable & consistent quality |

|

Competitive prices,Reliable & just in-time delivery |

|

|

Short delivery period |

|

|

Advanced technology |

|

|

Innovation and continuous improvement |

|

|

With vast experience of 30 years |

|

|

Technical support for applications / projects |

|

|

Product development for a changing market |

|

|

Product modification can be carried out according to customer requirements |